Metal Dual Interface or Contactless Smart Card and method for fabricating the same.

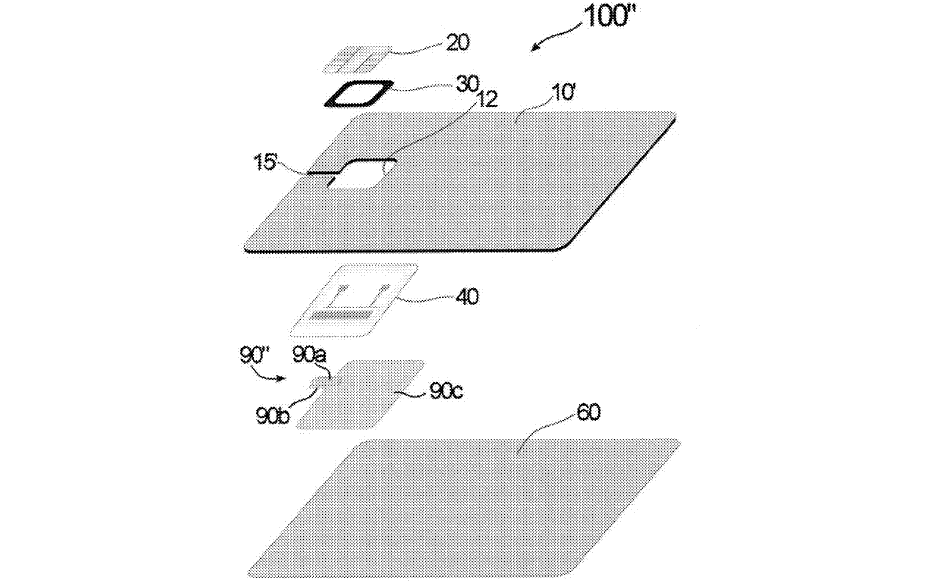

A metal contactless smart card includes a first metal layer having a first slit, a second layer, a radio-frequency integrated circuit chip module, and an inlay having an antenna. A non-conductive insert may be fitteed in the slit. The first metal layer may include an inlay recess where the inlay may be received and a through-hole where the chip may be inserted. The second layer of the smart card may be made of metal and may also include a slit.

Field of invention. The present invention relates to a metal contactless smart card, more paritcularly, to a metal smart card capable of communication by radio frequency or near-field-communication, and a method of fabricating the same.

Background of the invention. Smart cards using an integrated circuit chip or a combination of an IC chip and a magnetic strip are classified into contact types and contactless types. Contactless smart cards can employ radio-frequency (RF) communication or near-field-communication (NFC) to communicate with a compatible reader and have been used as credit cards, transportation passes, identification cards, membership cards, and the like.

While such cards are generally made substantially of plastic materials such as polyvinyl chloride (PVC), card issuing companies have found a need to produce metal cards, which can feel and look more sophisticated and higher in quality. Accordinly metal smart cards have grown in popularity in recent years, for example, credit card companies may issue metal credit cards to customers with high credit ratings or high net worth.

However, such metal smart cards have been by and large limited to contact types smart card. When metal layers are incorporated into contactless type smart cards, the attention of any kind of RF or NFC signal due to the presence of the metal layers often makes contactless metal cards unusable.

To overcome this problem, plastic contactless cards having thin metal film layers have been used. However, such films are susceptible to deterioration or discoloration. Additionally, a plastic card having a metal think film lacks the desirable heft of a card having substantial metal layers.

The introduction of a slit through a part of a metal sheet has been proposed to allow metallic layers to have contactless communication capabilities (for example through a metallic case of a smart phone). However, when incorporated into flat cards, the incorporation of the slit is detrimental to its structural properties. Namely, a card having a slit can be highly susceptible to cracking and breaking. Such fragility is not desirable in smart cards that are frequently handles and may be subject to flexing, dropping, or other abuse, For example, a credit card having a slit may be put into a wallet and subsequently be sat on resulting in the card breaking due to torional and normal stresses.

Therefore, there is a need for a metal contactless smart card that is durable. The invention is directed to address the above problems and satify a long-felt need.